Standing Rigging

Armare Ropes has developed a complete retrofit system to replace rod with textile standing rigging.

Armare standing rigging systems are the perfect choice for those who want to get the best from their boat, whether for a new project or a retrofit application, because it is easy to install and use, it doesn’t require many interventions on the current rigging and its maintenance is simple.

The cables are made of continuous PBO-Zylon multifilament, with the same techniques used for single cables. The apparent simplicity of these cables, hides a complex construction. Although it is always made with the “sling” system, and the production is handled by a special machine, that controls at any time tension and winding of the yarn, a considerable part of the work is done manually.

The result is a great attention to details, in particular those that are not visible, that’s to say treatments, finishes, protection and processes that are an important part in the construction of the cables. Actually these details affect the durability and the overall performance of the finished product.

STANDING RIGGING

Standing rigging:

the advantages

of textile systems

in PBO-Zylon®

Retrofit System

The development of alternative rigging solutions allow

for remarkable results in terms of lightness and performance,

thanks to the use of innovative high modulus fibers such as

PBO-Zylon®, Kevlar® and Dyneema®.

Armare Ropes tests and produces complete high-tech retrofit

solutions, thanks to the collaboration with professionals in the

rigging sector and the production of high-performance ropes,

made with high-tech fibers.

How does the system work

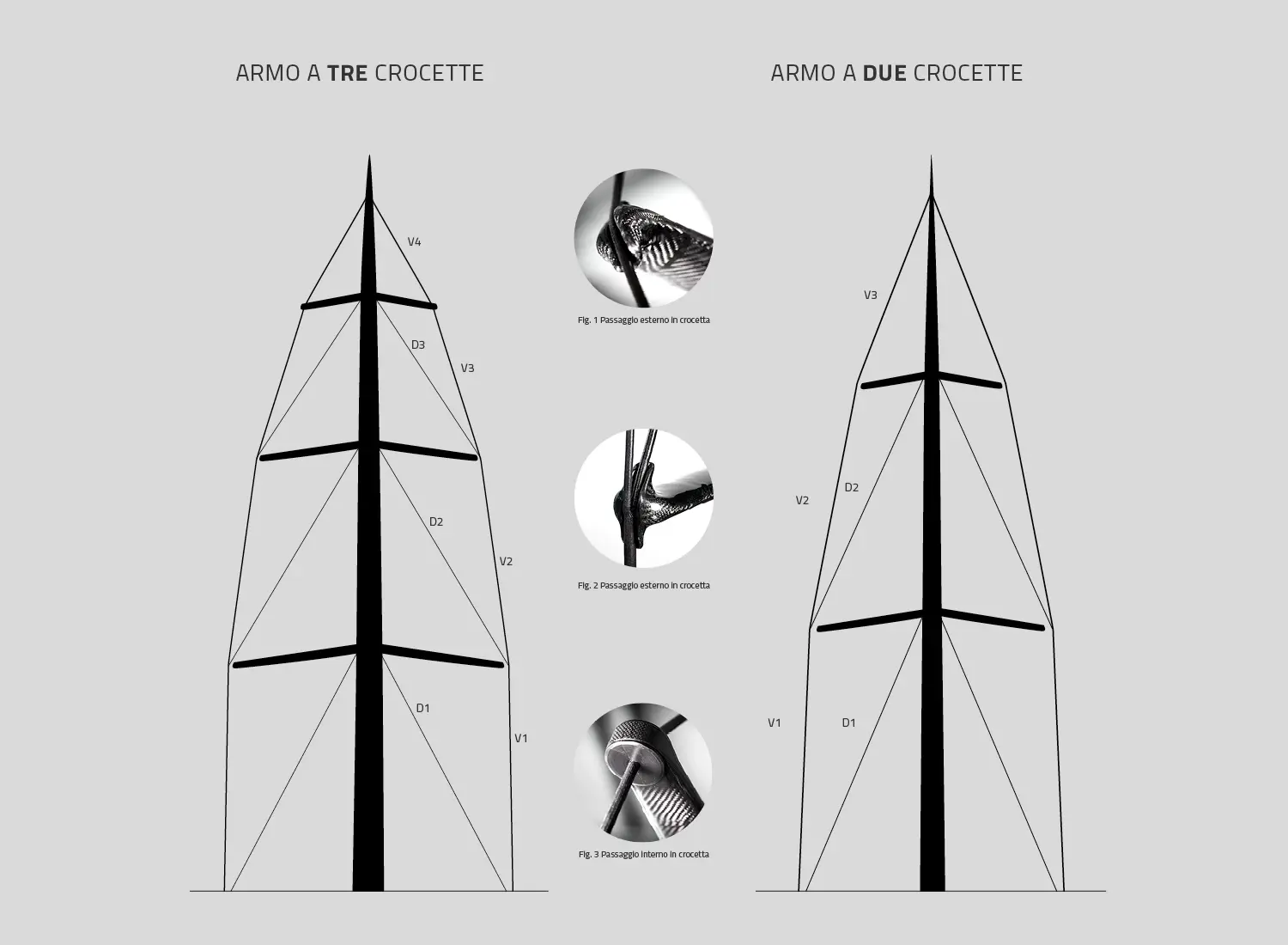

As shown in the figure below, the vertical (V1) and the diagonals (D1, D2, D3) are connected to the standard housing of the mast through the terminals, included in the textile standing rigging. Each steel fitting also has a regulation of about 70 mm. The vertical and the diagonals, excluding D1, are composed by a single cable, with the added benefit of a reduction of weight and complexity of the system.

External or internal spreader

There are two different techniques for the passage on the spreaders, that are called External spreader (Fig. 1 and 2) and Internal spreader / Tip Cup (Fig. 3).

In this way, for example, the passage of the vertical on the third spreader is completed with a simple binding, which keep in seat the cable, while the passage on the first spreader is inner, using the existing seats (Tip Cup). Any change to the heads of the spreaders are made directly from Armare. Finally, a simple steel fitting system allow the link between the deck cable (V1) and the diagonal (D1), that are taken to the right tension through special stainless steel turnbuckles.

Composite Cables

& Standing Rigging

Standing rigging systems in PBO-Zylon®, code cables, no-torsion cables, strops and steel fittings. Click the link below to download the PDF catalogue.