Endurance line ropes for offshore racing boats

Endurance line Armare is the result of several tests and feedback received from the best riggers, shore-teams and crews of the most prestigious racing boats worldwide.

The line includes single braids and double braid ropes; as these are special high-tech products, we recommend to contact armare ropes technicians for advice on developing the most ambitious rigging projects.

Endurance line

Top level ocean regatta and special projects

Endurance line groups highly performing ropes, characterized by special constructions with cores in Dyneema® and PBO-Zylon®.

4 different single braids in PBO-Zylon® and Dyneema® are available as well as 4 cores in Dyneema®, all characterized by special high-tech treatments that increase their performance.

The line is completed by 6 special covers that can be coupled to the cores.

Armare Ropes constantly collaborates with riggers, skippers and shore team engaged in setting up boats for the most important ocean regattas. Our technicians are available for the development of the special projects that this sector requires.

Endurance line

- > Single braid

- > Single braid (SHIELD)

- > Double braid (Core + Cover)

Select a single braid, or compose the rope in the configurator by choosing a core and a protective cover from the various available.

Endurance Line

Single braid

Single braid

- PBO TWPBO-Zylon® + PU

- TecforceBlack Technora® + PU

- Dyneforce Pure BlackDyneema® SK75 Pure Black + HPS

- Superound Pure BlackDyneema® SK75 Pure Black + PU

Single braid

Single braid SHIELD

Single braid SHIELD

- Dyneforce DM20SHIELD

- Dyneforce 99SHIELD

- Dyneforce 78SHIELD

- Superound 78SHIELD

Single braid SHIELD

Double braid

Cores

- Dyneema® DM20 ShieldHPS + SH

- Dyneema® SK99 ShieldHPS + SH

- Dyneema® SK78 ShieldHPS + SH

- Dyneema® SK78 ShieldSH

Covers

- PBO – Zylon®PBO

- PBO – Zylon® / Black Technora®PBO / BTEC

- PBO – Zylon / Black Dyneema®PBO / CDYN

- PBO – Zylon® / Black Technora®/ Black DynBPBO / BTEC / CDYN

- Black Technora®/ Black Dyneema®BTEC / BDYN

- Black Technora®/ Black Dyneema® / PetBTEC / BDYN / PET

Double braid

Special Treatments

Different special treatments may be applied to the braided cores and to the technical fibers to enhance their characteristics in terms of elongation, creep and resistance, and to obtain even better performance.

Single Braids

Endurance line

PBO TW (PBO – Zylon® + PU)

Designed to equip the best sail boats, PBO-Zylon® guarantees the lowest elongation, a high breaking load, elevated mechanical resistance and optimal flexibility. Moreover, theelevated stability on winches and stoppers, the lightweight and its good handling make this rope the excellent partner of the most demanding crews.

Tecforce (Black Technora® + PU)

Particularities of this aramid fiber are its good resistance to UV rays and to bending if compared to other standard aramid fibers; both properties allow to obtain long lasting ropes with a good breaking load and a low elongation. A very oriented molecular structure guarantees a high modulus with a low creep. Tecforce is therefore mainly used for bindings, reinforcements as well as for all those applications where an important breaking load but also a high resistance to abrasion and elongation are required.

Dyneforce Pure Black (Dyneema® SK75 Pure Black + HPS + PU)

The already well-known performances of our former Dyneforce75 (replaced by Dyneforce 78) will be proposed again yet in its new version Dyneema® SK 75 BK. The main characteristic of this fiber, named Dyneema® Pure Black, consists in having a colour that can’tbe attacked by any agent, since the fiber is dope-dyed. Besides its remarkable technical performances, the aesthetic is given by the colour that won’t fade over time.

Superound Pure Black (Dyneema® SK75 Pure Black + PU)

The renewed version of this specific item, made with Dyneema® SK75 BK (or Dyneema® Pure Black) maintains its basic features and on top of that the fiber is dope-dyed. The result is a long-lasting colour that doesn’t fade over time, while excellent technical performances are guaranteed.

Single Braids Shield

Endurance line

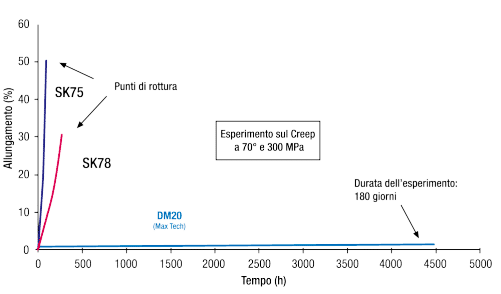

Dyneforce DM20 SHIELD

Dyneema® DM20 has been created to satisfy specific marine/industrial needs. Compared to other types of Dyneema®, it shows better performance in terms of durability over time as well as a close to zero creep. Its very stable construction allows Armare to produce a rope that is suitable for all those applications where a constant load and a continued use would put to the test any other type of Dyneema®. Furthermore, the Shield treatment increases the compactness and the abrasion resistance of this rope.

Use: It is the ultimate solution for strops, shrounds, backstays and halyards on hydraulic cylinder but also for stable and long-lasting bindings.

Dyneforce 99SHIELD

Dyneema® SK99 delivers the highest tenacity available in a light weight polymer fiber. Indeed, compared to Dyneema® SK78, it shows a 20% increase on tenacity and a 35% higher modulus. Dyneema® SK99 appears thinner and lighter weight respect to ropes with the same diameter, but with a significant increase in strength, which entails an increase on performance and a better response of the boat. Moreover, thanks to the application of the Shield treatment, the ropes results more compact and more resistant to abrasion. Other features: low water absorption, high UV resistance, minimal elongation and good flexibility.

USE: Ideal for tackles, backstays, runners, baby stays, halyards on hydraulic cylinders, strops and loops; moreover for bindings where high breaking load, low elongation and minimal amount of space are required.

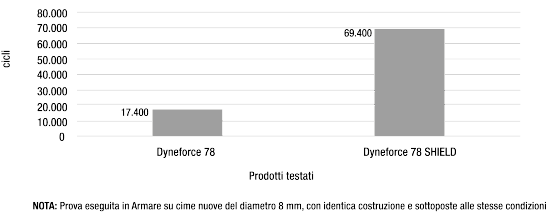

Dyneforce 78SHIELD

The High Modulus fiber Dyneema® SK78, characterized by a remarkable stability under constant loads, provides the following features: low creep and elongation, elevated breaking load, light weight, low level of water absorption, high resistance to UV rays, great flexibility. Furthermore, the Shield treatment increases the compactness and the abrasion resistance of this rope. The ropes made with this core are destined to extreme performances, especially during highly demanding regattas when the permanent load is continuously present.

USE: Ideal for tackles, backstays, runners, baby stays, control lines, strops and loops; moreover for bindings where a good breaking load and a low elongation are required.

Superound 78 SHIELD

Line of ropes differs from the previous version Dyneema® SK78 + HPS + SHIELD in the lack of the HPS treatment, which means that there is no thermic pre-stretching under load. This makes the rope more manageable, as the core is more supple. It has a slightly different breaking load and elongation in comparison with DYN 78 + HPS + SHIELD, because the braid is not settled (it means that the differences of tensions between fibers are not adjusted). However, its general features remain at a high level, making this rope affordable to boats and crews of a less extreme technical level.

USE: Ideal for bindings, leading blocks, control lines and tackles.

SPECIAL TREATMENT

Endurance Special Treatments

Pure Black Dyneema

Thanks to Dyneema® BK (BLACK), nowadays we are able to produce a black rope totally made with Dyneema® without degradation of colour. This process allows to obtain a stable and long lasting coloring of the fibre without any compromise in terms of durability and resistance to UV rays.

Shield Treatment

Shield is a new special treatment developed and introduced by Armare Ropes, which consists in the supercial impregnation of the braid, with the aim of improving the performance and duration of the finished product.

Shield Cores

Endurance line

Dyneforce DM20 HPS

Dyneema® DM20 has been created to satisfy specific marine/industrial needs. Compared to other types of Dyneema®, it shows better performance in terms of durability over time as well as a close to zero creep. Its very stable construction allows Armare to produce a rope that is suitable for all those applications where a constant load and a continued use would put to the test any other type of Dyneema®.

Use: It is the ultimate solution for strops, shrounds, backstays and halyards on hydraulic cylinder but also for stable and long-lasting bindings.

Dyneforce 99 HPS

Dyneema® SK99 delivers the highest tenacity available in a light weight polymer fiber. Indeed, compared to Dyneema® SK78, it shows a 20% increase on tenacity and a 35% higher modulus. Dyneema® SK99 appears thinner and lighter weight respect to ropes with the same diameter, but with a significant increase in strength, which entails an increase on performance and a better response of the boat. Other features: low water absorption, high UV resistance, minimal elongation and good flexibility.

USE: Ideal for tackles, backstays, runners, baby stays, halyards on hydraulic cylinders, strops and loops; moreover for bindings where high breaking load, low elongation and minimal amount of space are required.

Dyneema® SK78 HPS

The High Modulus fiber Dyneema® SK78, characterized by a remarkable stability under constant loads, provides the following features: low creep and elongation, elevated breaking load, light weight, low level of water absorption, high resistance to UV rays, great flexibility. The ropes made with this core are destined to extreme performances, especially during highly demanding regattas when the permanent load is continuously present.

USE: Ideal for tackles, backstays, runners, baby stays, control lines, strops and loops; moreover for bindings where a good breaking load and a low elongation are required.

Dyneema® SK78

Line of ropes differs from the previous version Dyneema® SK78 + HPS + SHIELD in the lack of the HPS treatment, which means that there is no thermic pre-stretching under load. This makes the rope more manageable, as the core is more supple. It has a slightly different breaking load and elongation in comparison with DYN 78 + HPS + SHIELD, because the braid is not settled (it means that the differences of tensions between fibers are not adjusted). However, its general features remain at a high level, making this rope affordable to boats and crews of a less extreme technical level.

USE: Ideal for bindings, leading blocks, control lines and tackles.

Covers

Endurance line

PBO – Zylon® (PBO)

Unbeatable resistance to abrasion and heat. Thanks to its properties, it is the best choice among the range of technical ropes in the applications where high temperatures and elevated loads are constantly present.

USE: This cover is especially used for runner tackles, high friction/load sheets and also for hi-loads takles.

PBO – Zylon® / Black Dyneema® (PBO / CDYN)

Thanks to the presence of PBO®, this cover has a high resistance to abrasion. The right mix with Dyneema® fibre transfers a good fluidity to the ropes when released on winch under load. Tests on racing boats have demonstrated the amazing durability to high frequency movements of the cover. The presence of Pure Black Dyneema® gives this cover a technical look, complian to the design of the best racing yachts.

USE: The best choice to protect sophisticate cores in a super technical running rigging system, where high loads are the main stress for the rope

PBO – Zylon® / Black Technora® (PBO / BTEC)

First rate resistance to abrasion and high temperature Thanks to the balance of two excellent fibers its properties are perfect for the intensive uses onboard of the competitive yacht racing.

USE: High loads and temperature don’t scare this rope and it’s a good solution for afterguys and runner sheets.

PBO – Zylon® / Black Technora® / Black Dyneema® (PBO / BTEC / CDYN)

This cover is the ideal choice for running rigging subjected to high loads or high temperatures. Moreover, it is suitable for all those manoeuvers where very fast recoveries are necessary as it avoids the melt of the fibers and damages that affect the life of the cover. The mixture of three different high-performance fibers guarantees a remarkable durability and smoothness as well as an excellent resistance to abrasion and heat, thanks to the high melting point of the basic fibers.

USE: Endurance is a must-have for the use on spinnaker/gennaker sheets, spinnaker/gennaker halyards, runner tails.

Black Technora®/ Black Dyneema® (BTEC / CDYN)

The mixture of these fibres has been carefully studied to be fairly distributed in order to make them take advantage of their mutual characteristics, both in terms of durability and performance. Excellent results in order of smoothness, abrasion resistance and durability have been reached. The presence of Pure Black Dyneema® gives this cover a solid black colour, accordant to the needs of the top racing yachts.

USE: Ideal for high fatigue manoeuvres and repeated mechanical stress, in particular where the wear of the cover is steadily present e.g. jib sheets, tacklines and staysail sheets.

Black Technora ® / Black Dyneema ® / Poliestere (BTEC / CDYN / PET)

This item is suitable for many different boats and uses because of its excellent resistance to abrasion and to repeated bending. Compared to TEC/DYN covers, it is easer to customize thanks to the presence of Polyester and it even becomes more recognizable in the distinction of the different manoeuvres. Furthermore, the use of the Pure Black Dyneema® gives this cover a solid black colour, accordant to the needs of the top racing yachts.

USE: Ideal for jib and gennaker sheets, halyard and control lines.

Composite Cables

Textile Standing Rigging

Catalogue dedicated to composite cables and standing rigging systems in PBO-Zylon and Kevlar, strops and steel fittings.

Related News

Discover the new 2025 Colour Chart

Since customization has always been a key element for Armare Ropes, we are pleased to introduce our 2025 Colour Chart,...

Read MoreArmare Ropes visited the Emirates Team New Zealand base in Barcelona.

Armare Ropes visited the Emirates Team New Zealand base in Barcelona as the Official Supplier of the New Zealand team....

Read MoreArmare Ropes at the Bernetti Trophy with the Conference “Made in FVG Ropes Leading in the America’s Cup”

On the occasion of the 53rd Bernetti Trophy, one of the most important sailing events in the Gulf of Trieste,...

Read MoreWhat a great success at the Olympics

The 2024 Sailing Olympics ended yesterday in Marseille. Italy achieved its best historical result at the Olympic Games, with two...

Read MoreNuovo rig Armare Ropes per Kookaburra III

Kookaburra III (KA 15) is one of those boats that you can’t forget, even after 35 years! She was in...

Read MoreAC75 Taihoro has landed

Emirates Team New Zealand’s AC75 Taihoro has safely arrived at the team base in Barcelona after a 28-day journey travelling...

Read MoreLorenz Line, a new arrival in One Design line

Lorenz Line is a new line of Armare Ropes lines, specifically developed for use on high-load maneuvers on small dinghies....

Read MoreArmare PBO runners on Cape 31 OD

Another prestigious class joins the already long list of One Designs with Armare Ropes PBO products onboard. This time the...

Read More